Construction and fitout of multiple projects on the Bausch + Lomb campus in the IDA Park, Waterford.

Project Overview

We were appointed to construct several projects on the Bausch + Lomb campus in the IDA Park, Waterford, namely:

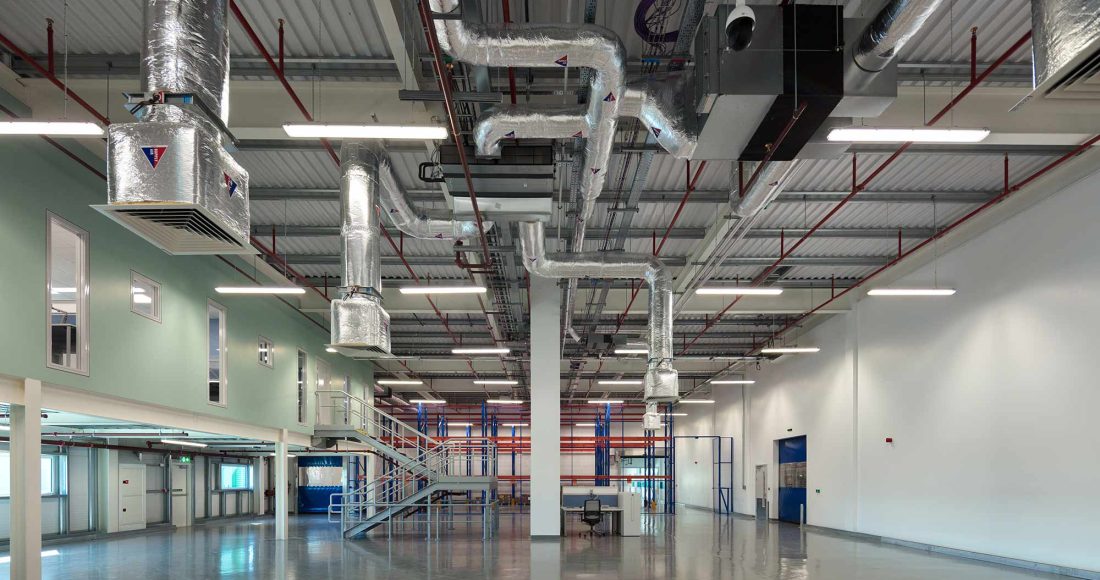

FCE Area 8.0: Construction of a new building on the northern side of the campus comprising of a new two-storey production building with roof level plant area. The new building comprises four ISO 8 cleanrooms for contact lens manufacture with an overall floor area of 5,676m² including laboratories, testing and sterilisation areas, office and staff accommodation, canteen, and coldrooms.

Phase 5.2: Construction of a single storey link corridor and a new façade on the overhead recessed first floor. The works consisted of an alteration and extension to existing production, packaging and workshop facilities, storage areas, minor internal modifications to offices and staff ancillary accommodation, along with a rooftop plant room extension.

Finance Offices: A fitout project comprising a complete overhaul of the existing finance offices. New works included floors, walls, ceilings, glazed screens, and a kitchenette.

Phase 6.2: An existing materials handling area was transformed into a live production zone. Two-storey high block walls built between a structural steel frame were demolished to extend the existing space, whilst maintaining a live production area. Cleanroom walls, floors and ceilings were erected along with all required services and service equipment poles. A plant mezzanine was constructed internally with a steel frame and concrete floor while the live plant remained operational at all times.

Phase 6.3: A new warehouse type extension adding a further steel portal, flat roof and Kingspan clad envelope. New dock levellers and loading bay doors were constructed onto a reconfigured marshalling yard.

The Bausch + Lomb facility is a bonded manufacturing site and operates 24/7. This presented the challenge of delivering a world-class manufacturing expansion without any disruption to the existing operations. We achieved this through phased working, and maintaining all critical live services, utilities and plant throughout.

The project was completed without any reportable accident or incident during construction. The site had numerous visits from the Health and Safety Authority (HSA), who commended us for the high standard of EHS maintained on site on each visit. To this end, the HSA used this site to launch their BeSMART programme in the southeast region.

Key Features

- Phased working within and adjacent to a live pharmaceutical manufacturing facility

- Provision of new production, packaging and storage facilities, laboratories, offices, staff accommodation, and delivery facilities including loading docks and associated marshalling yards.

- Four ISO 8 cleanrooms for contact lens manufacture (5,676m²)

- Fitout project comprising a complete overhaul of the existing finance offices with new floors, walls, ceilings, glazed screens and a kitchenette

- All associated plant and equipment, site works, parking facilities and alterations to internal road network and drainage

- Integrated coordination, installation and validation of plant, equipment, and all specialist services

- Maintaining all critical live services, utilities and plant

- LEED Silver rating

Project Team

Client:Bausch + Lomb Ireland

Architect:

C.J Falconer & Associates

Quantity Surveyor:

MacMinn, O’Reilly, Mahon

Structural Engineer:

Frank Fox & Associates

M&E Consultant:

Synergy Engineering Waterford Ltd

Project Details

Floor Area:15,000m²

Duration:

20 months