A bridge maintenance contract for Transport Scotland involving tidal scour repair works to Cromarty Bridge along with the removal of sediment from around the bridge abutments.

Project Overview

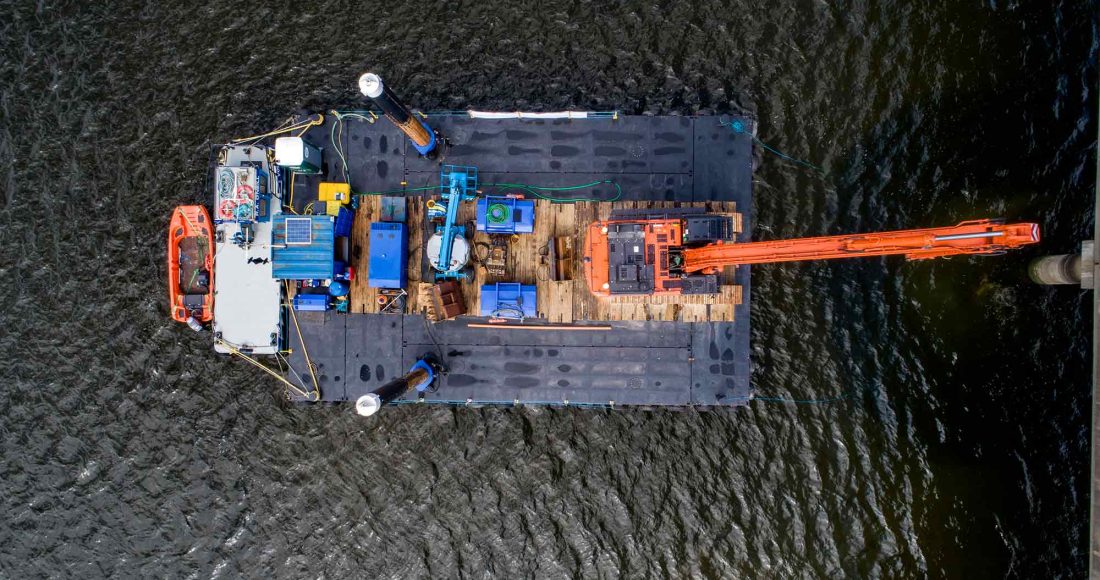

Following a scour survey to examine the sea bed levels surrounding the pile caps on the Cromarty Bridge (A9 north of Inverness), Transport Scotland identified scour around a number of the piers, exposing the top of the piles in some cases. Loss of the bed material below the pier foundations could result in local and global structural failure. Thus, we were appointed to carry out tidal scour repair works and remove sediment from around the bridge abutments under a bridge maintenance contract for Transport Scotland who required specialist works undertaken as part of a larger bridge maintenance programme. Additional works undertaken included the removal of all vegetation and the jet washing/cleaning of the concrete piers, including the inspection of the concrete piers for any signs of concrete fatigue and failure. We also undertook a limited amount of concrete remediation to isolated parts of the structure. The works were completed entirely from marine barges and required extensive environmental measures to be put in place due to otters, seals and Arctic terns in the area.

Significant temporary works, including floating pontoons and access scaffolding to the work areas and the base of the bridge piers, were designed and implemented. Spud legs were utilised on the floating pontoon manoeuvred by tug boats to secure the stability of the pontoon during the works. Temporary road closures were also required to allow the installation of the spud legs on the barge. All closures were kept to an absolute minimum and outside peak traffic hours. All closures were restricted to two hours to allow the lifting and placing of the spud legs. An emergency route across the bridge had to be maintained at all times due to the length of the diversion, which was unacceptable for emergency services. Temporary safety barriers were installed along the length of the works area across the bridge. This had no impact on the traffic, but added additional traffic management safety for the workforce on the bridge.

The precision excavations around the pile caps were carried out using GPS controlled excavators, which were also used to install 3,000 tonnes of rock armour to the riverbank. The dive team consisted of a five professional commercial divers with an appointed dive supervisor.

The works were tidal, with a range in water levels of +/- 5m, therefore, all works had to be planned according to the tide levels. To minimise the work underwater with the divers, the geotextile membrane was pre-cut and fabricated to the size of the piers, which reduced the divers bottom time and increased their safety.

Key Features

- Precision excavations around pile caps with GPS-controlled excavators

- 3000tn of rock armour placed from barges by GPS-controlled excavators

- Reclamation/screening of excavated sea bed material to fill voids under pile caps with diver-controlled pumping

- Pump backfill material into the voids, where present under the pile caps

- Pumped material to be secured by geotextile and rock armour

- Performing limited amount of concrete remedials to isolated parts of the structure

- Planning/navigation of material, work barges and Multicats due to tidal variances of 5m

- Quayside logistical planning for material supply, storage and loading

- Environmental mitigation measures due to Otters, Seals, and Arctic Tern breeding colony

- Extensive planning for material supply, storage and loading

Project Team

Client:Transport Scotland

Structural Engineer:

Jacobs Engineering

Project Details

Contract Value:€5.3 Million

Floor Area:

1,140m Bridge length

Duration:

9 months

Location:

Scotland